The Practical Application of Laser Protection Plates in Laser Cutting

Release time: 2025-11-11

Laser cutting has become widely used in various fields such as metal processing, automotive manufacturing, electronic product processing, and more. Due to its high efficiency and precision, laser cutting has become an indispensable processing method in many industries. However, the high temperature and energy of the laser beam during the cutting process can pose certain risks to equipment and the surrounding environment. To protect the equipment and enhance operational safety, laser protection plates have gradually become an essential component in laser cutting operations.

1. Basic Functions of Laser Protection Plates

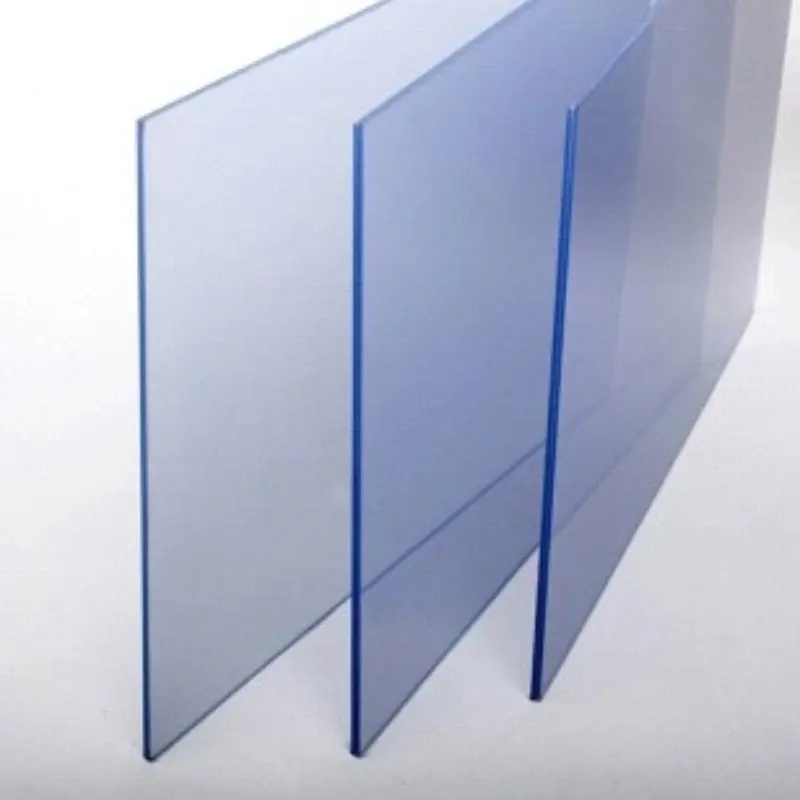

As the name suggests, laser protection plates are materials used to protect laser equipment and operators from laser radiation, reflection, and high temperatures. They can effectively absorb and reflect laser beams, preventing direct exposure to the laser, which could damage equipment or the operating environment. Typically, laser protection plates are made from special materials that offer high heat resistance, wear resistance, and laser radiation protection.

2. Practical Application of Laser Protection Plates in Laser Cutting

1. Protecting Laser Equipment

During laser cutting, the optical path and mirrors of the laser equipment are vulnerable to damage from the heat and radiation of the laser beam. Laser protection plates can effectively shield these precision devices. By installing suitable protection plates, the equipment surface is prevented from being burned by the laser spot, which helps to extend the life of the equipment.

2. Reducing Laser Reflection and Contamination from Laser Spots

During the laser cutting process, some laser beams may be reflected or scattered. Without effective protection measures, these reflected beams can affect the surrounding environment or interfere with other equipment. Laser protection plates absorb and effectively reflect the laser beams, preventing any reflected light from causing damage to the operating environment.

3. Ensuring Operator Safety

Laser radiation can be harmful to operators’ eyes and skin, especially during laser cutting machine operations. Laser protection plates provide a protective barrier around the laser cutting area, preventing laser radiation from directly exposing the operator’s skin or eyes, thus ensuring operator safety. The transparency of the protection plate allows operators to clearly observe the cutting process without being affected by laser radiation.

4. Improving Cutting Quality

Laser beam stability is crucial for cutting quality. Laser protection plates not only protect laser equipment and operators but also help control the laser beam’s path and temperature changes, reducing the heat-affected zone and ensuring stable cutting quality. Additionally, the heat isolation capabilities of the protection plates help prevent overheating from affecting the cutting material, reducing material deformation.

5. Enhancing the Cleanliness of the Working Environment

During the laser cutting process, laser protection plates help prevent metal vapor, smoke, and dust from contaminating the environment. These fine particles, under the influence of high-temperature lasers, could become harmful substances. The use of laser protection plates helps isolate these contaminants, ensuring the cleanliness and safety of the factory environment.

3. Choosing and Installing Laser Protection Plates

Selecting the right laser protection plate material is key to ensuring the safety and efficiency of the cutting equipment. Different types of laser protection plates vary in material, thickness, heat resistance, and other properties. Therefore, the choice should be based on the specific laser cutting machine model, processing materials, and working environment requirements.

- Material Selection: High-strength transparent materials, such as polycarbonate (PC), are commonly used for laser protection plates. They effectively block most laser radiation while maintaining good visibility.

- Thickness and Heat Resistance: Depending on the cutting power and temperature requirements, the appropriate thickness of the protection plate should be chosen. High-power laser cutting requires thicker protection plates to prevent heat damage.

- Installation Position: Laser protection plates are typically installed around the laser optical path or within the laser cutting equipment’s operational area, ensuring they can effectively block laser radiation and provide protection.

4. Conclusion

Laser protection plates have become an essential measure in laser cutting operations to improve equipment safety, ensure cutting quality, and protect the operators. Choosing the right laser protection plate can not only extend the lifespan of equipment but also enhance the overall production process’s efficiency and safety.

If you have any questions or would like to learn more about laser protection plates, feel free to contact Flomc. We are committed to providing you with professional advice and high-quality product solutions.