How to reduce the failure rate of production-related equipment through anti-static sheets

Release time: 2025-06-24

In the modern production industry, static electricity has become one of the main factors affecting the stable operation of equipment, especially in the field of high-precision equipment and electronic manufacturing. Electrostatic discharge (ESD) not only causes equipment damage, but may also have adverse effects on product quality. In order to effectively reduce the failure rate of equipment and extend its service life, the use of anti-static sheets has become an effective solution.

Table of Contents

The harm of static electricity to production equipment

The impact of static electricity problems on equipment and production environment cannot be underestimated. Static electricity accumulation can lead to the following problems:

Equipment damage: The high voltage and current generated by static electricity discharge may burn key components such as circuit boards and sensors, and in severe cases, it may cause equipment shutdown.

Frequent equipment failures: Static electricity accelerates equipment aging, increases the failure rate, and the cost of repair and replacement rises accordingly.

Affecting product quality: Static electricity not only damages equipment, but may also cause product quality problems in the production process and increase the production of defective products.

Production line stagnation: Production shutdowns caused by equipment failures directly affect output value and cause delays in production progress.

Therefore, controlling static electricity accumulation and protecting equipment from its damage is the key to ensuring equipment operation.

The role of anti-static sheet

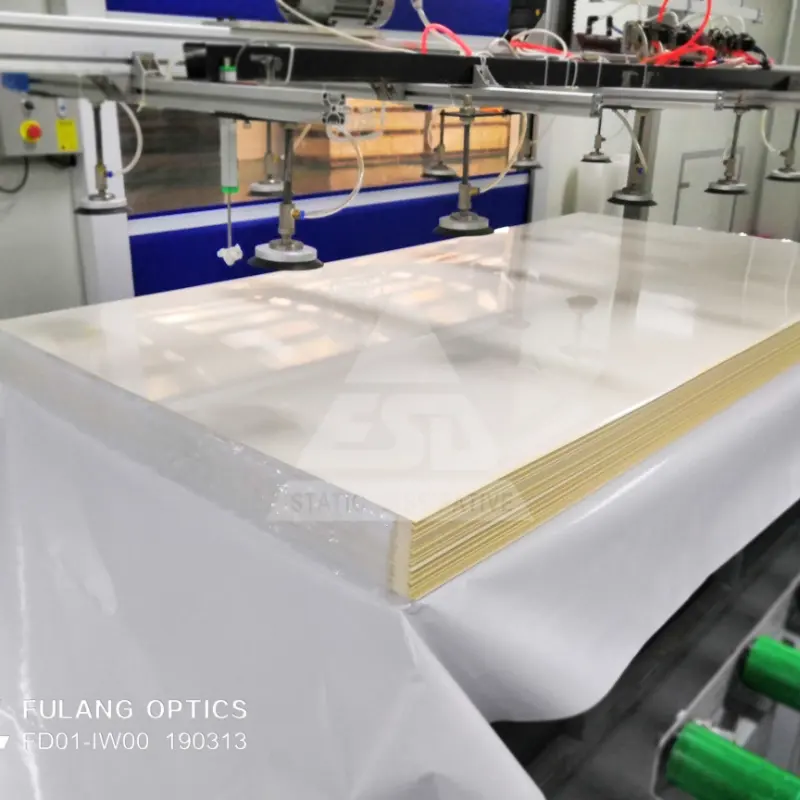

Anti-static sheet is treated with special technology, which can effectively inhibit the accumulation of static electricity and reduce the occurrence of static discharge, thereby protecting production equipment. The PVC, PC and PMMA anti-static sheets provided by Flomc have superior static suppression ability and stable physical properties, which can meet the needs of various production environments.

The benefits of using anti-static sheet include:

1.Inhibit static accumulation: anti-static sheet can quickly absorb and export static electricity, avoid static accumulation from the source, and reduce the risk of static discharge.

2.Extend equipment life: effectively reduce the damage of static electricity to equipment, extend the service life of equipment, and reduce maintenance and replacement costs.

3.Improve production efficiency: Controlling static accumulation can reduce production stagnation caused by equipment failure and ensure the continuous operation of the production line.

4.Improve product quality: After the interference of static electricity on the production process is reduced, the stability and quality of the product are improved, and the defective rate is reduced.

Advantages of anti-static sheet provided by Flomc

Our company provides anti-static sheets of various sizes, colors and materials to meet the needs of different industrial environments. Whether it is regular size or customized size, we can provide you with the most suitable solution.

Multiple size options:

Standard size: antistatic PVC 1250*2450, antistatic PC 1240*2420, antistatic PMMA 1240*2460

Customized size: According to the production environment and equipment requirements, we provide tailor-made anti-static sheets to ensure comprehensive protection around the equipment, production lines and other key areas.

Multiple color options:

Our anti-static sheets are available in a variety of colors. Customers can choose the appropriate color according to environmental requirements or brand image to ensure that both function and visual effects are given equal importance.

Efficient static control:

The PVC, PC, and PMMA anti-static sheets we use can still effectively control static accumulation and ensure the safety of equipment and production environment even in environments with high humidity or large temperature changes.

Strong durability:

The anti-static sheet has strong impact resistance, high temperature resistance and corrosion resistance, and can be used stably for a long time in harsh working environments, reducing the occurrence of equipment failures.

How to choose the right anti-static sheet?

Choosing the right anti-static sheet depends on your production needs and equipment characteristics:

anti-static PVC sheet: suitable for general industrial environments, good anti-static performance, and high cost performance.

anti-static PC sheet: suitable for environments with high temperature and high impact resistance requirements, and can provide stronger protection.

anti-static PMMA sheet: suitable for industries that require transparency and have high requirements for anti-static, providing excellent static control effect.

Flomc provide customized services, tailor-made the most suitable anti-static solution according to your specific needs, to help you protect your equipment and ensure smooth production.

Conclusion

Static electricity is an important factor affecting production equipment management and product quality, especially in the manufacturing process of high-precision electronic equipment. By choosing high-quality anti-static sheets, you can not only reduce the equipment failure rate and extend the service life of the equipment, but also improve production efficiency and product quality.

The PVC, PC, and PMMA anti-static sheets we provide can perfectly adapt to your production needs with a variety of colors, sizes and customization options. Choose us and you will enjoy a more stable and safe production environment.

Contact Flomc now to learn more about anti-static sheets and let us help you create an efficient production environment without static electricity, protect equipment, and improve efficiency!