विस्तृत पैरामीटर

आधुनिक औद्योगिक उत्पादन में, उत्पाद की गुणवत्ता और उपकरणों के सुचारू संचालन को सुनिश्चित करने के लिए स्थैतिक विद्युत का नियंत्रण और प्रबंधन एक महत्वपूर्ण कारक बन गया है। विशेष रूप से इलेक्ट्रॉनिक्स, अर्धचालक और ऑटोमोटिव निर्माण जैसे उच्च तकनीक वाले उद्योगों में, इलेक्ट्रोस्टैटिक डिस्चार्ज (ESD) उपकरणों को नुकसान, उत्पादन में रुकावट और यहाँ तक कि गुणवत्ता संबंधी दुर्घटनाओं का कारण बन सकता है। इसलिए, उत्पादन लाइनों की सुरक्षा के लिए एंटीस्टेटिक सामग्रियों का उपयोग अत्यंत महत्वपूर्ण है।. एंटीस्टेटिक पैनल, स्थैतिक बिजली नियंत्रण के लिए एक प्रभावी समाधान के रूप में, कई उद्योगों में उत्पादन लाइनों की सुरक्षा के लिए पसंदीदा विकल्प बन रहे हैं।.

एंटीस्टेटिक पैनल क्या हैं?

एंटीस्टेटिक पैनल विशेष प्रक्रियाओं और सामग्रियों द्वारा निर्मित सामग्री हैं जिनमें एंटीस्टेटिक, सुचालक, या इलेक्ट्रोस्टैटिक अपव्यय गुण होते हैं। इनका मुख्य कार्य स्थैतिक विद्युत संचय को कम करना और इलेक्ट्रोस्टैटिक डिस्चार्ज (ESD) से उपकरणों, उत्पादों या कर्मियों को होने वाले नुकसान को रोकना है। एंटीस्टेटिक पैनल का व्यापक रूप से इलेक्ट्रॉनिक उत्पादन लाइनों, स्वच्छ कक्षों, प्रयोगशालाओं और अन्य वातावरणों में उपयोग किया जाता है जहाँ स्थैतिक विद्युत नियंत्रण के लिए सख्त आवश्यकताएँ होती हैं।.

एंटीस्टेटिक पैनलों के प्रमुख लाभ

- स्थैतिक विद्युत खतरों की प्रभावी रोकथाम

एंटीस्टेटिक पैनल स्थैतिक विद्युत को प्रभावी ढंग से अवशोषित या नष्ट करते हैं, जिससे इलेक्ट्रोस्टैटिक डिस्चार्ज की घटना कम होती है। चाहे वह इलेक्ट्रॉनिक उपकरणों, सटीक उपकरणों, या कार्मिक कार्यों से उत्पन्न स्थैतिक विद्युत हो, ये सामग्रियाँ एक निवारक भूमिका निभा सकती हैं, जिससे उपकरणों को नुकसान, डेटा हानि, और स्थैतिक विद्युत के कारण होने वाली अन्य संभावित समस्याओं का जोखिम कम होता है।. - उन्नत उत्पादन क्षमता और सुरक्षा

इलेक्ट्रोस्टैटिक डिस्चार्ज न केवल उपकरणों की दीर्घकालिक स्थिरता को प्रभावित करता है, बल्कि उत्पादन लाइन में रुकावट, खराबी का निदान मुश्किल होने और अन्य समस्याओं का कारण भी बन सकता है। एंटीस्टेटिक पैनल इन जोखिमों को काफी हद तक कम कर सकते हैं, उत्पादन लाइनों के निरंतर और स्थिर संचालन को सुनिश्चित करते हुए, इस प्रकार समग्र उत्पादन दक्षता में सुधार कर सकते हैं। इसके अतिरिक्त, इनका उपयोग इलेक्ट्रोस्टैटिक डिस्चार्ज के कारण होने वाले रखरखाव लागत और रुकावट को कम करने में मदद करता है।. - विशिष्टताओं और अनुप्रयोगों की विविधता

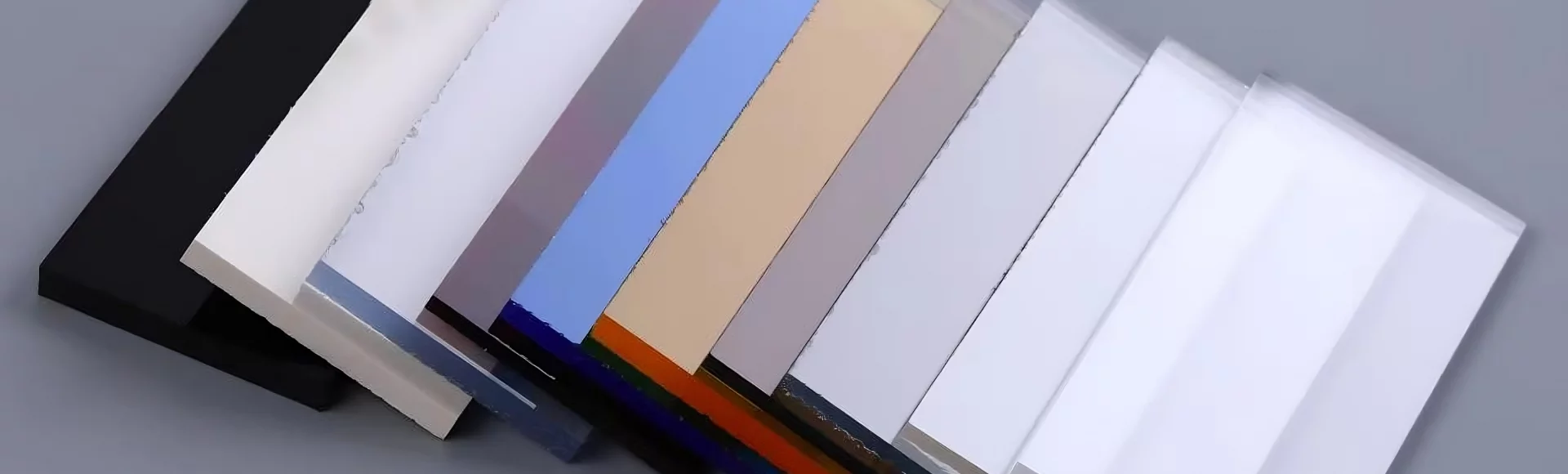

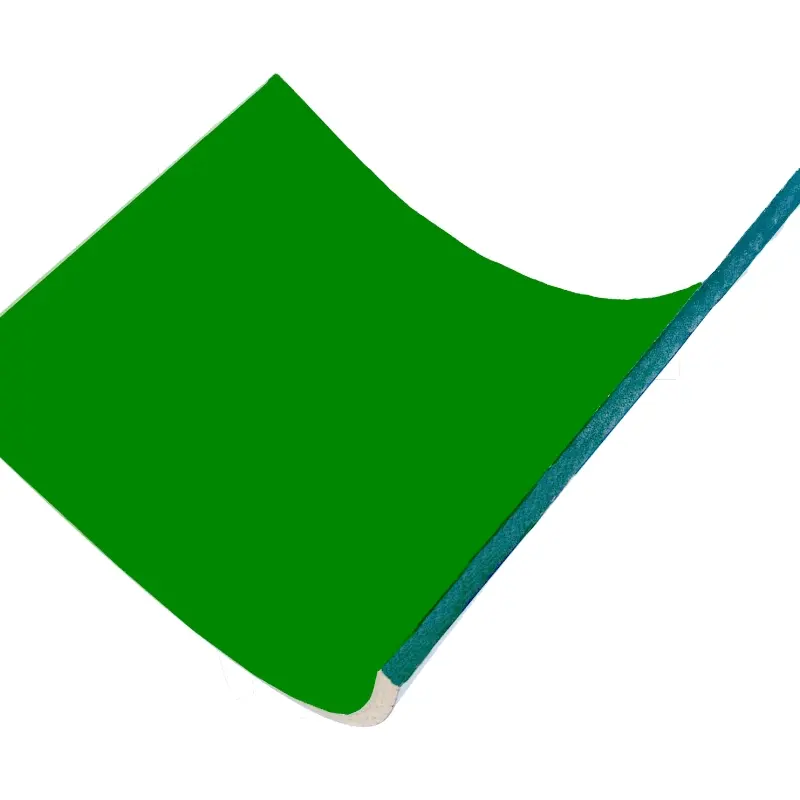

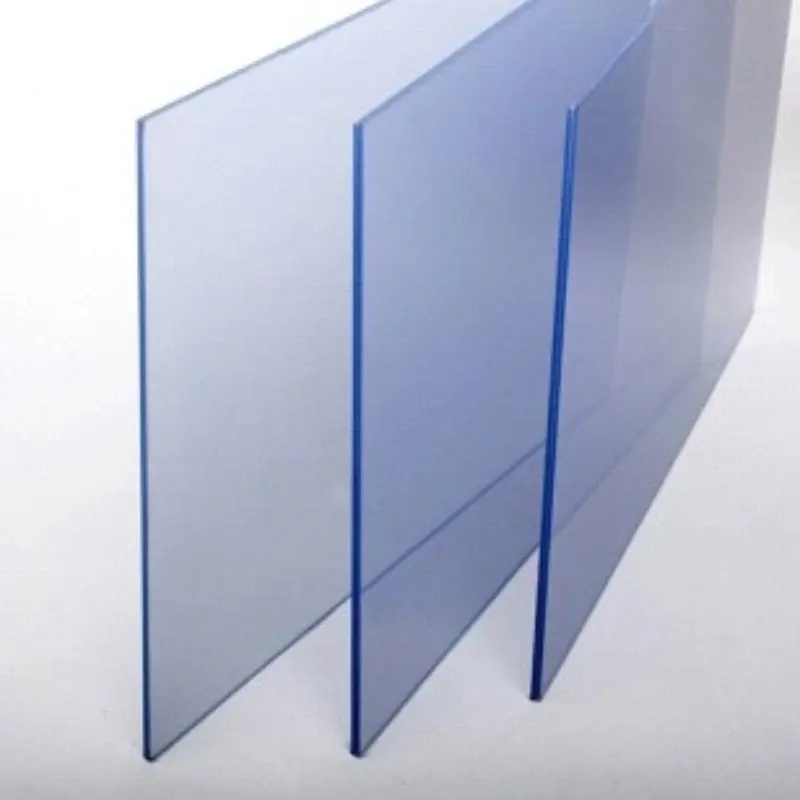

एंटीस्टेटिक पैनल विभिन्न आकारों, मोटाई और रंगों में आते हैं, जो उन्हें विभिन्न उत्पादन वातावरणों और आवश्यकताओं के लिए उपयुक्त बनाते हैं।. - पर्यावरण मित्रता और स्थिरता

आधुनिक एंटीस्टेटिक पैनल आमतौर पर पर्यावरण के अनुकूल सामग्रियों से बनाए जाते हैं जो प्रासंगिक पर्यावरणीय मानकों को पूरा करते हैं। पारंपरिक प्लास्टिक पैनलों की तुलना में, एंटीस्टेटिक पैनल न केवल अधिक पर्यावरण के अनुकूल होते हैं, बल्कि रसायनों के उपयोग और प्रदूषण को कम करने में भी मदद करते हैं, जिससे उत्पादन लाइन की सुरक्षा सुनिश्चित करते हुए उद्यम के सतत विकास में योगदान मिलता है।.

एंटीस्टेटिक पैनलों के सामान्य अनुप्रयोग

- इलेक्ट्रॉनिक्स विनिर्माण

इलेक्ट्रॉनिक उपकरणों के उत्पादन की प्रक्रिया में, स्थैतिक विद्युत घटकों के साथ हस्तक्षेप कर सकती है, जिससे क्षति या प्रदर्शन में गिरावट आ सकती है। उत्पादों और ऑपरेटरों पर स्थैतिक विद्युत के प्रभाव को प्रभावी ढंग से रोकने के लिए, एंटीस्टेटिक पैनल आमतौर पर वर्कस्टेशन, असेंबली प्लेटफॉर्म और उत्पादन लाइनों पर भंडारण क्षेत्रों में उपयोग किए जाते हैं।. - सेमीकंडक्टर उद्योग

अर्धचालक उत्पादन में, इलेक्ट्रोस्टैटिक डिस्चार्ज चिप्स को नुकसान पहुँचा सकता है, जिससे उत्पादन क्षमता प्रभावित होती है। एंटीस्टेटिक पैनल का उपयोग अर्धचालक निर्माण उपकरण, परीक्षण उपकरण और स्वच्छ क्षेत्रों में किया जाता है, जो उत्पादन लाइन के लिए स्थिर स्थैतिक सुरक्षा प्रदान करते हैं।. - ऑटोमोटिव विनिर्माण

ऑटोमोटिव उद्योग में इलेक्ट्रॉनिक उपकरणों की बढ़ती माँग के साथ, स्थैतिक विद्युत का प्रबंधन अत्यंत महत्वपूर्ण हो गया है। एंटीस्टेटिक पैनल असेंबली लाइन पर संवेदनशील ऑटोमोटिव इलेक्ट्रॉनिक उपकरणों की प्रभावी रूप से सुरक्षा करते हैं, जिससे ऑटोमोटिव इलेक्ट्रॉनिक प्रणालियों को स्थैतिक विद्युत से होने वाले नुकसान से बचाया जा सकता है।. - स्वच्छ कमरे और प्रयोगशालाएँ

एंटीस्टेटिक पैनल का व्यापक रूप से स्वच्छ कक्षों, प्रयोगशालाओं और अन्य विशिष्ट वातावरणों में उपयोग किया जाता है। इन वातावरणों में स्थैतिक विद्युत नियंत्रण के लिए कठोर आवश्यकताएँ होती हैं, और एंटीस्टेटिक पैनल यह सुनिश्चित करने में मदद करते हैं कि संवेदनशील उपकरण, नमूने और अभिकर्मक स्थैतिक विद्युत से प्रभावित न हों, जिससे प्रयोगों की सटीकता और उपकरणों के समुचित संचालन की गारंटी मिलती है।.

सही एंटीस्टेटिक पैनल कैसे चुनें?

- एप्लिकेशन परिवेश को समझें

एंटीस्टेटिक पैनल चुनते समय, सबसे पहले अनुप्रयोग परिदृश्य और पर्यावरणीय आवश्यकताओं को समझना ज़रूरी है। अलग-अलग उत्पादन वातावरणों में स्थैतिक विद्युत नियंत्रण की अलग-अलग ज़रूरतें होती हैं, और अलग-अलग प्रकार की एंटीस्टेटिक सामग्रियों की ज़रूरत हो सकती है। उदाहरण के लिए, उच्च तापमान या उच्च आर्द्रता वाले वातावरण में, उच्च तापमान या संक्षारण प्रतिरोधी पैनल चुने जाने चाहिए।. - पैनल के प्रवाहकीय गुणों का निर्धारण करें

विभिन्न एंटीस्टेटिक पैनलों में अलग-अलग चालक गुण होते हैं। कुछ पैनल इलेक्ट्रोस्टैटिक अपव्यय के लिए उपयुक्त होते हैं, जबकि अन्य चालक निर्वहन के लिए डिज़ाइन किए जाते हैं। चयन करते समय, कार्यस्थल की स्थैतिक विद्युत प्रबंधन आवश्यकताओं के आधार पर सही चालक गुणों वाले उपयुक्त पैनल का चयन करना महत्वपूर्ण है।. - सामग्री की स्थायित्व और गुणवत्ता पर विचार करें

उत्पादन लाइन की सुरक्षा के लिए एंटीस्टेटिक पैनलों की गुणवत्ता और टिकाऊपन बेहद ज़रूरी है। उच्च-गुणवत्ता वाले पैनल चुनने की सलाह दी जाती है जो ज़्यादा समय तक चलते हैं और बेहतर घर्षण प्रतिरोध प्रदान करते हैं, जिससे रखरखाव की लागत और बदलने की आवृत्ति कम होती है।. - मानकों और प्रमाणन की जाँच करें

उच्च-गुणवत्ता वाले एंटीस्टेटिक पैनल आमतौर पर प्रासंगिक अंतर्राष्ट्रीय प्रमाणपत्रों, जैसे IEC, UL, आदि के साथ आते हैं, जो उत्पाद की गुणवत्ता और सुरक्षा सुनिश्चित करते हैं। इसलिए, खरीदते समय, प्रमाणित उत्पाद प्रदान करने वाले ब्रांड और आपूर्तिकर्ताओं का चयन करना उचित है।.

निष्कर्ष

आधुनिक उत्पादन लाइन सुरक्षा में एक प्रमुख घटक के रूप में, एंटीस्टेटिक पैनल न केवल इलेक्ट्रोस्टैटिक डिस्चार्ज के खतरों को प्रभावी ढंग से रोकते हैं, बल्कि उत्पादन लाइनों की स्थिरता और सुरक्षा में भी सुधार करते हैं। सही एंटीस्टेटिक पैनल का चयन इलेक्ट्रॉनिक्स, अर्धचालक और ऑटोमोटिव निर्माण जैसे उद्योगों के सुचारू संचालन को सुनिश्चित कर सकता है। स्थैतिक विद्युत नियंत्रण की बढ़ती मांग के साथ, एंटीस्टेटिक पैनल विभिन्न उद्योगों में एक अनिवार्य भूमिका निभाते रहेंगे।.

हमसे संपर्क करें

एक पेशेवर के रूप में एंटीस्टेटिक पैनलों के आपूर्तिकर्ता, एफएलओएमसी हम विभिन्न औद्योगिक वातावरणों के लिए उपयुक्त विभिन्न आकारों और विशिष्टताओं में एंटीस्टेटिक पैनलों की एक विस्तृत श्रृंखला प्रदान करते हैं। हमारे उत्पाद अंतरराष्ट्रीय गुणवत्ता मानकों को पूरा करते हैं, जिससे आपकी उत्पादन लाइनों को सर्वोत्तम सुरक्षा मिलती है। यदि आपकी कोई आवश्यकता हो, तो बेझिझक हमसे संपर्क करें, और हम आपको सबसे पेशेवर उत्पाद और सेवाएँ प्रदान करेंगे।.

दूरभाष:0555-3833736

ई-मेल:floomc1111@gmail.com

अनुशंसित उत्पाद

यदि आप हमारे उत्पादों में रुचि रखते हैं, तो कृपया जानकारी प्रस्तुत करने के लिए नीचे दिया गया फॉर्म भरें।