Analysis of the key role of anti-static PVC sheet in the electronics industry

Release time: 2025-06-09

In the electronics industry, the damage of electrostatic discharge (ESD) to electronic components has always been an issue that cannot be ignored. With the continuous development of science and technology, electronic equipment has become increasingly miniaturized and sophisticated, and the harm of static electricity has become more and more significant. In order to ensure the effective control of static electricity in the production and use environment, the application of anti-static materials has become particularly important. As a widely used anti-static material, anti-static PVC sheet plays a vital role in the electronics industry.

What is anti-static PVC sheet?

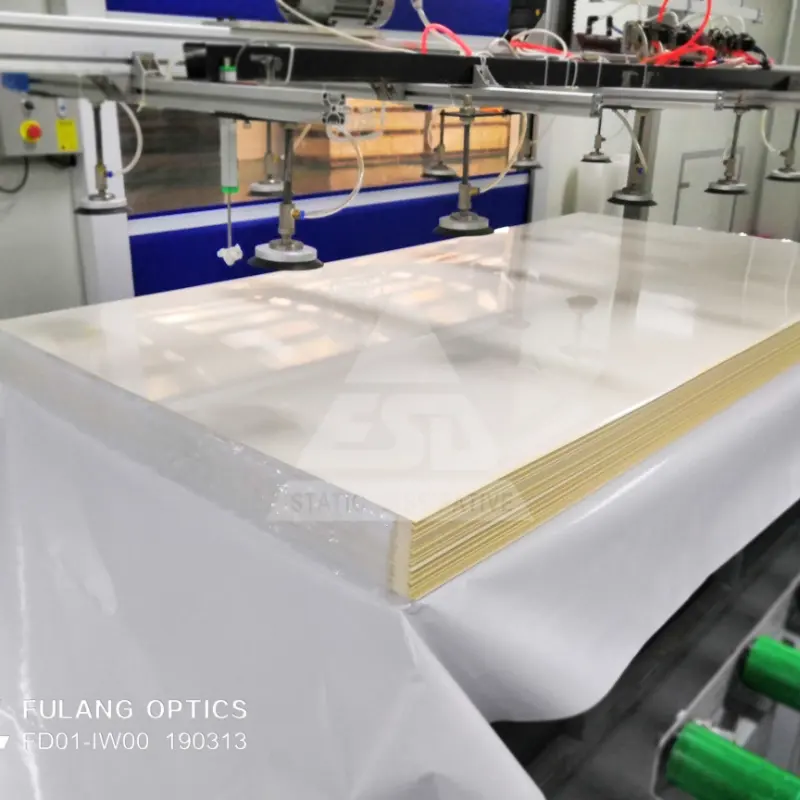

Anti-static PVC sheet is a specially treated polyvinyl chloride (PVC) sheet with antistatic coating on its surface, which can effectively inhibit the accumulation of static electricity and avoid the damage of static discharge to electronic components. This material has the excellent properties of PVC itself, such as chemical resistance, weather resistance and wear resistance, and can provide reliable static protection.

The role of anti-static PVC sheet in the electronics industry

Protecting sensitive electronic components

In the process of electronic manufacturing and assembly, electrostatic discharge (ESD) is one of the main causes of component damage. Electronic components such as microchips, circuit boards, and semiconductors are very sensitive, and even weak electrostatic discharge may cause irreparable damage. ESD PVC board can reduce the accumulation of static electricity through effective antistatic treatment, thereby effectively protecting these sensitive components.

Reduce the impact of static electricity on the production environment

The production environment of electronic products usually requires a high standard of dust-free and static-free environment. Antistatic PVC board can be widely used in electronic production lines, workbenches, test equipment and other areas to ensure that static electricity in the operating environment is effectively suppressed and reduce the interference of static electricity on the production process, thereby improving product quality and production efficiency.

Prevent static electricity from damaging product quality

Electrostatic discharge not only damages the electronic components themselves, but also may affect the performance and quality of the entire product. During the production process, static discharge may cause problems such as circuit board short circuit, chip burnout, and equipment failure, which often have an adverse effect on the function and reliability of the product. The application of antistatic PVC board can effectively isolate the source of static electricity and prevent static electricity from damaging product quality.

Improve employee work safety

For employees engaged in electronic assembly, maintenance and other work, contact with static electricity may cause discomfort or even electric shock. The use of antistatic PVC board can reduce the accumulation of static electricity, which not only protects electronic components, but also ensures the safety of employees at work.

Reduce operating costs

In the long run, anti-static PVC sheets can effectively reduce equipment failures and product damage caused by static electricity, and avoid maintenance costs and rework costs caused by static electricity damage. By improving production stability and product qualification rate, anti-static PVC sheets can help companies save a lot of operating costs.

Application areas of anti-static PVC sheets

Anti-static PVC sheets are widely used in the following electronic industry fields:

Electronic component production and assembly: Anti-static PVC sheets are used in production lines, workbenches, floors and other areas to prevent static electricity from damaging components.

Clean rooms and laboratories: In places where strict environmental control is required, anti-static PVC sheets are often used as floor and workbench materials.

Packaging and storage: Anti-static PVC sheets can also be used in packaging boxes and storage cabinets for electronic components to protect sensitive components from static electricity.

Static protection equipment: Anti-static PVC sheets are widely used in equipment such as static protection boxes and shielding cabinets to ensure that the static environment of the equipment is in a safe state.

Frequently Asked Questions (FAQ)

- What is anti-static PVC sheet?

Anti-static PVC sheet is a specially treated PVC board with an anti-static coating on its surface, which can effectively inhibit the accumulation of static electricity and avoid damage to electronic components caused by static discharge. - What industries are anti-static PVC sheets suitable for?

Anti-static PVC sheets are widely used in electronics, semiconductors, precision instruments, medicine and other industries, especially in production sites where static electricity environment needs to be strictly controlled. - What are the advantages of anti-static PVC sheets?

Effectively inhibit static electricity accumulation and prevent damage to components caused by static electricity discharge.

Good chemical resistance, wear resistance and weather resistance.

Easy to process, cut and install.

Environmentally friendly, safe, non-toxic and harmless. - How to clean and maintain anti-static PVC sheets?

It is recommended to use a damp cloth or soft brush for cleaning, and avoid using detergents containing strong acids or strong alkalis. Clean the surface regularly to maintain the anti-static properties of the board. - How long is the service life of anti-static PVC sheets?

Under normal use and maintenance, the service life of anti-static PVC sheets is usually long, and can generally be used for several years. - Can anti-static PVC sheets withstand high temperatures?

The temperature resistance range of anti-static PVC sheets is usually between -10°C and 60°C, which is suitable for general indoor environments. For high temperature environments, it is recommended to choose more suitable high temperature resistant materials.

Through this article, you can better understand the key role of anti-static PVC sheets in the electronics industry. If you have any questions or needs, please feel free to contact Flomc, we will provide you with more information and services.